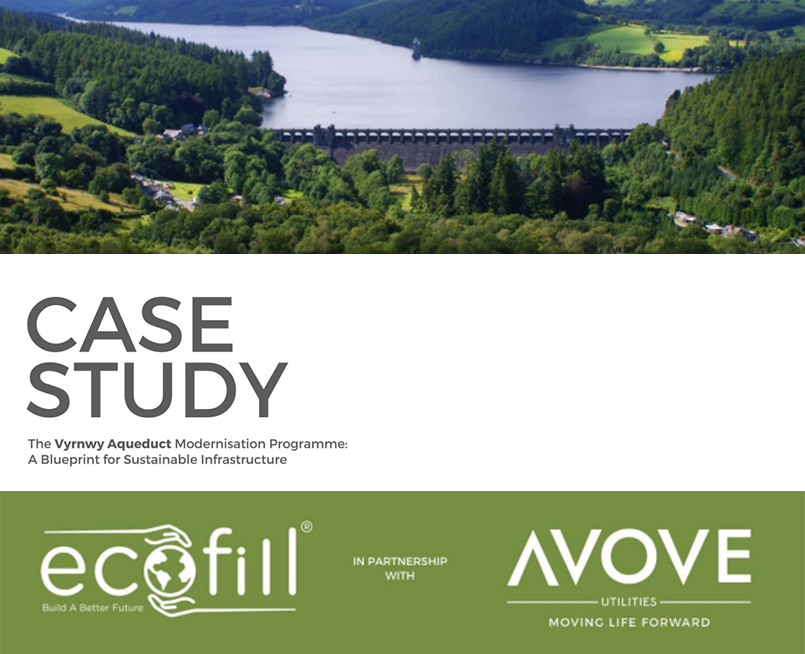

Avove and Ecofill partner to deliver sustainable earthworks solutions

We have joined forces with Ecofill and are leveraging groundbreaking technology to reduce aggregate use, lorry movements, carbon emissions and costs as well as protect agricultural land and leave a positive legacy in local communities.

Protecting agricultural land with Ecofill

The sustainable Ecofill technology transforms clean and contaminated clays and subsoils into aggregate replacement products.

Upgrades to utility services are part of everyday life. As part of this, we are required to build temporary structures such as haul roads, access roads, compounds and working platforms. Traditional construction methods produce temporary structures by excavating the existing soil, and in its place, importing thousands of tonnes of aggregates from miles away. This entails countless lorry loads going to and from site which is costly and carbon intensive and highly disruptive to neighbouring towns and villages. Aggregates generate a significant proportion of our industry’s waste and also contribute massively to the industry’s carbon footprint.

Working in partnership with Ecofill, we are offering an alternative solution to provide an on-site process combining state-of-the-art machinery with environmentally friendly, specially formulated binders that transform all types of clays and subsoils into fully certified, aggregate replacement products. Once the structures reach the end of their design life, Ecofill ensures a solid decommissioning process that restores the ground to its original pH and nutrient status. Supported by a robust Inspection Test Plan and Quality Management Plan, Ecofill provides unwavering quality assurance, all summarised in a handover Validation Report for client and landowner peace of mind.

This process, which is being trialled at the Vyrnwy Aqueduct Modernisation Programme, will bring significant reductions in the requirement to import and export aggregates. It will reduce CO2 emissions, costs, road traffic and social disruption, whilst improving site safety.